A kitchen remodel asks a lot of your house. You are bringing in bigger appliances, brighter lighting, new outlets at every turn, and more power-hungry conveniences than the original builder imagined. Get the electrical plan right, and the space feels effortless. Get it wrong, and you live with nuisance breaker trips, shadows on your prep surface, or a range hood that sounds like a jet every time the microwave runs. Partnering with an experienced American Electric Co electrician early keeps the design practical, code‑compliant, and future‑proof.

How a Working Kitchen Drives the Electrical Plan

A cooking space sets a unique rhythm. You chop near the sink, move to the range, slide to the oven, then back to the counter to finish. Lighting and outlets should anticipate that path. I think about kitchens in zones, not just a grid of receptacles. Task zones need generous, shadow-free light. Counter zones demand outlets with enough spacing for mixers, coffee grinders, and an occasional crockpot. Cleanup zones invite moisture, so we introduce GFCI protection and select devices that tolerate occasional splashes. And the appliance core, where the refrigerator, dishwasher, microwave, and oven live, demands separate circuits sized to each load.

The earlier you involve an electrician, the easier it is to coordinate these zones with cabinet drawings and appliance specs. An electrical contractor American Electric Co brings a practiced eye for where code flexibility exists, where it doesn’t, and where a small design shift avoids a costly rework later.

Start with the Panel: Capacity, Space, and Service

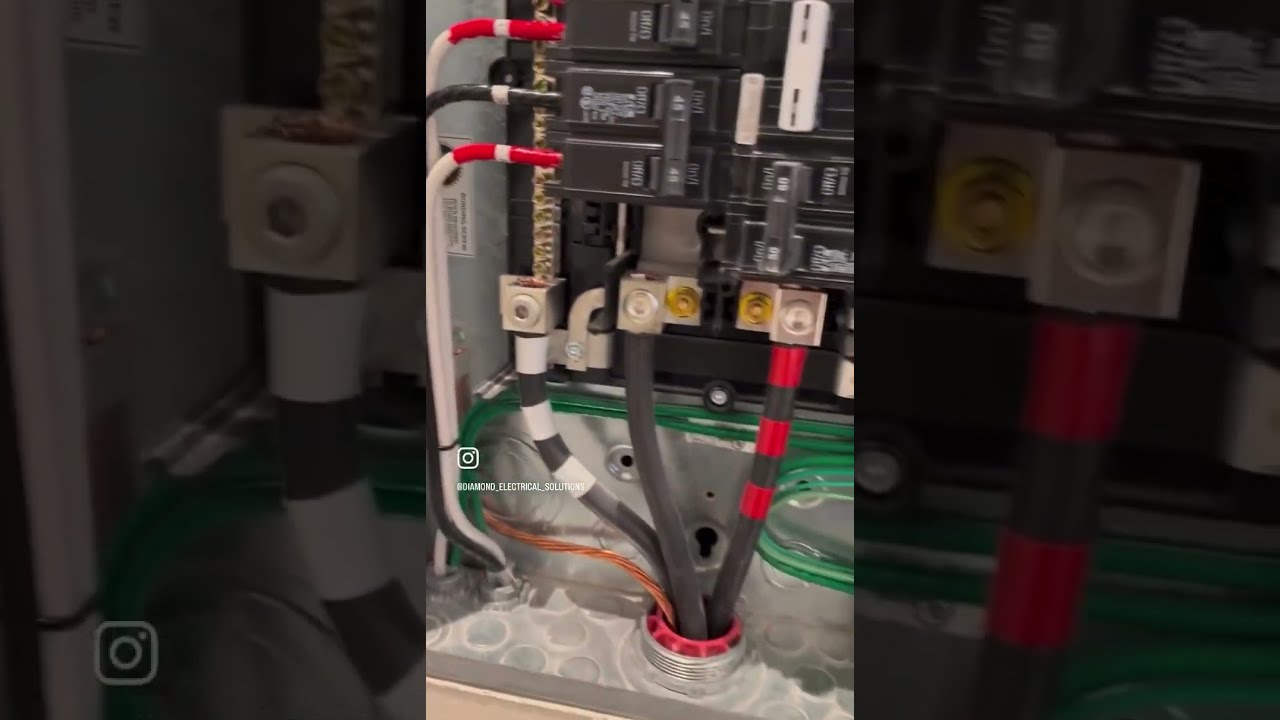

Before we dream about pendants and pop-up outlets, we look at the service. A surprising number of homes still run on 100‑amp panels. That might have worked in the 1980s with a gas range and a small microwave, but add a double wall oven, induction cooktop, drawer microwave, and under‑cabinet lighting, and you can push past the headroom quickly.

An American Electric Co electrician will do a load calculation. It isn’t a guess. We tally the fixed appliances, the small appliance circuits that code requires, and the general lighting load. If you are also planning a heat pump, EV charger, or backyard hot tub, we fold those into the picture. Often the answer is a service upgrade to 200 amps, or at least a subpanel near the kitchen to localize circuits and relieve congestion in the main panel. I have seen kitchens that needed six to ten dedicated circuits just for appliances, plus lighting and counter receptacles. If your panel is already near full, you want standby generator installation service to know that before the drywall goes back up.

Circuits by Appliance: Sizing, Location, and Reality Checks

Every brand publishes installation guides, but they are not all equally helpful. We read the label on the appliance, not just the brochure. The label tells the actual amperage. A smart electrician from American Electric Co will cross‑check the nameplate against the breaker size so the circuit works the way the manufacturer intended.

- Refrigerators usually run on a 15 or 20 amp, 120‑volt dedicated circuit. I still prefer dedicated even if the code allows sharing in some jurisdictions. It avoids nuisance trips when holiday baking fills the counter with gadgets. Dishwashers and disposals can share a circuit in specific configurations, but I tend to separate them. Modern dishwashers heat water internally. That load plus a disposal start surge can push a shared 15‑amp circuit too close for comfort. Microwaves, especially drawer or built‑in types, want a 20‑amp circuit. Countertop models plugged into small appliance circuits are fine, but built‑ins deserve their own breaker. Electric ranges and wall ovens often need a 40 to 50 amp, 240‑volt circuit. Induction can be efficient, yet it still demands a heavy feeder. Don’t pick the wire based on a “typical” draw. Confirm the exact model. Beverage fridges, wine coolers, and ice makers add up. They look small, but three or four of them can equal a full‑size refrigerator’s draw.

A good practice is to leave a spare conduit or an extra run from the panel to a junction space behind the cabinets. I have had clients add a steam oven or switch to induction two years later. A little foresight during framing saved them a day of fishing cable through finished walls.

Two Small Appliance Circuits Are the Floor, Not the Ceiling

National code calls for at least two 20‑amp small appliance circuits serving countertop receptacles. In a real kitchen, two is often not enough. Picture a weekend brunch with a waffle iron, a stand mixer, a toaster, and a kettle going. Plus, a phone charger or two wants a piece of that power. Rival devices with heating elements spike load as they cycle. If the layout is large or includes a long island, adding a third small appliance circuit smooths life out. An American Electric Co electrician will divide the runs so the island and perimeter aren’t competing for the same amps, which reduces tripping.

Spacing matters too. Receptacles on the counter should be close enough that no spot is farther than 24 inches from one. Islands need outlets, though how many and where depends on cabinet design and local code interpretations. If a waterfall edge or drawer stack complicates placement, we’ll look at under‑counter receptacles tucked beneath overhangs or furniture‑style pop‑ups rated for the location. They are not all equal. The good ones are wet‑location rated and have robust seals. Cheaper units fail after a few steamy dishwashing sessions.

GFCI and AFCI: Protection Without the Mystery

Safety devices should fade into the background, not become a riddle when a tripped breaker leaves the fridge dark. Kitchens typically require GFCI protection for receptacles that serve the countertop, sinks, and many fixed appliances within a specified distance of water. Now add AFCI requirements for branch circuits to protect against arc faults. Combination GFCI/AFCI breakers or dual‑function breakers at the panel can protect all downstream outlets cleanly. That choice keeps bulky GFCI devices from crowding your backsplash, and it avoids multiple reset points.

There are exceptions and local nuances, which is another reason to bring in an electrician who works these kitchens daily. I like to label the panel directory american electric co clearly so anyone can find and reset the right breaker fast. During the final walk‑through, I show the homeowner where GFCI or dual‑function protection lives so there’s no panic at the first trip.

Lighting Layers that Actually Work

A kitchen with a single ceiling fixture feels dim even when the bulb is bright. A practical plan uses three or four layers: ambient light to fill the room, task light on the counters, accent light to define the island or shelves, and a softer path light for night movement. Dimming each layer independently adjusts the mood and function without a switch maze.

Recessed fixtures do the heavy lifting for ambient light. I like smaller trims, 3 or 4 inches, spaced to prevent scalloping. Over the sink, a dedicated recessed light centered on the basin keeps you from washing dishes in your own shadow. For task lighting, continuous LED tape or puck fixtures under the upper cabinets erase the dark stripe at the backsplash. Warm‑to‑cool tunable tape can shift from a crisp 3500 to 4000 Kelvin when you prep, back to 2700 to 3000 for dinner. Consistency matters: pick a color temperature range and stick with it across fixtures. Mismatched whites make a pristine kitchen look off.

Pendant lights over the island are both jewelry and work light. I measure their height after the countertop is templated. Islands vary in thickness, and a pendant hung based on a guess often ends up too low or off center once the slab goes in. An American Electric Co electrician will leave extra whip in the box and return after counters are set to hang and aim lights precisely.

If the space opens to a family room, consider downlight trims with a higher color rendering index, ideally 90 CRI or better. Greens and reds in food look fresher, and wood tones in the cabinetry read true. It’s a subtle difference that your eyes feel even if you can’t name it.

Smart Controls without the Overkill

Not every kitchen needs a touch screen. Thoughtful switching goes a long way. I divide controls into logical groups near the main entry and a secondary set by the patio door or mudroom entry if that is a common route. A multi‑location dimmer for the main lights keeps you from walking in to harsh brightness late at night.

For clients who want smart capability, I aim for simple and resilient. A few scenes cover most scenarios: full prep lighting, dinner mode with pendants warm and bright, late night pathway with toe‑kick lights at 10 percent. Choose a system that still works from the wall if the app acts up. An American Electric Co electrician can spec devices that integrate with the rest of the house, so you don’t end up with three different platforms just to turn on lights.

Toe‑kick and cove lighting deserve a mention. Low‑level LED strips on a dedicated circuit become a favorite feature for families with early risers or teens who raid the fridge at midnight. It’s inexpensive during framing and delightful after move‑in.

Venting, Hoods, and Make‑Up Air

People obsess over BTUs and forget that the hood and its power supply matter just as much. A high CFM hood often needs a dedicated circuit and, in many jurisdictions, a make‑up air solution tied to that hood. If you pull 600 to 1200 cubic feet per minute out of a tight house, you create negative pressure that affects the furnace, water heater, and comfort. There are code thresholds that trigger make‑up air requirements, but even below the line, you should plan for how the house breathes.

Some hoods come with integral lighting that wants dimming. Not every hood light plays nicely with every dimmer. We check the spec sheet and use compatible controls to prevent flicker. The same goes for inline or rooftop blowers where the motor control lives away from the hood. It takes coordination between the electrician and HVAC installer so the wiring and low‑voltage controls meet in the right box.

Hidden Details that Save Headaches

A remodel gets messy behind the scenes. Old houses have surprises baked into the walls. You open a plaster chase and find knob‑and‑tube remnants, undersized boxes, or shared neutrals that throw modern GFCI/AFCI devices into a tizzy. An American Electric Co electrician anticipates these landmines. We test at the start, not the day before inspection.

Box fill is a small detail that becomes a big issue fast. Stack a multi‑gang switch box with several smart devices and travelers, and you can exceed volume limits. I spec deeper boxes where possible and leave wire neatly dressed and labeled. Same story with appliance cutouts. Warming drawers and ovens want junction boxes accessible but hidden. We coordinate those locations with the cabinet maker so doors and drawers clear.

If you are planning under‑cabinet outlets integrated into the cabinet bottoms or rail systems, order lead times can be long. These products change the wiring route and box count. Tell your electrician about them before rough‑in. I have had clients discover a sleek rail system on Instagram after drywall, then realize it needs low‑profile raceways we didn’t plan for. It is fixable, but it costs time.

Islands and Peninsulas: Power without Clutter

An island looks clean until you need a place to plug in a blender. Then every option feels like a compromise. Side‑mounted outlets near seating zones are practical, but you must protect them from kicks and chair impacts. I aim for the back of a cabinet gable or discreet locations under an overhang. For larger islands, a pair of outlets keeps cords from stretching across cutting boards.

Waterfall stone complicates the picture. Some clients will accept a pop‑up on the top surface. The good ones seal well and carry proper listings for countertop use. If you dislike the look, we can mount receptacles in shallow pockets beneath the overhang. The American Electric Co team has built custom shims to angle outlets slightly downward so cords hang neatly and the face disappears from common sight lines.

Grounding and Bonding When Metal Comes Into Play

Modern kitchens mix materials. Metal shelves, stainless counters on an island prep station, or a pot‑filler near an induction top change the grounding picture. You do not bond every piece of metal like a commercial kitchen, but you should not ignore conductive paths that could carry fault current. When we introduce a metal channel lighting system or LED profiles in cabinet undersides, we verify the listed method for bonding. It’s not glamorous, but it keeps nuisance trips and odd shocks at bay.

Kitchens That Age Gracefully

No remodel freezes life. Kids grow. Interests change. A coffee bar becomes a baking station. Reserve capacity and flexible infrastructure help the kitchen adapt. During rough‑in, I often run one extra multi‑wire branch circuit to a capped junction tucked inside a cabinet, labeled and mapped. If someone adds a secondary oven or high‑draw appliance later, we already have a safe, legal path to power it.

USB‑C outlets are popular, though they evolve quickly. I prefer swappable wall plates or modular chargers so you are not locked into a dated standard embedded in a $60 device. And I put at least one standard duplex outlet near the coffee station that isn’t burdened with USB guts, because a burr grinder or espresso machine wants all the amperage it can legally draw from a 20‑amp receptacle.

Budget Priorities That Pay Off

Clients sometimes ask where to save and where to spend. A few trade‑offs I recommend after years of seeing what lasts:

- Spend on panel capacity and clean circuiting. It prevents costly rework and supports future upgrades. Choose quality dimmers and drivers for LED strips. Cheap controls cause flicker and early failure. Invest in under‑cabinet lighting that delivers even, continuous illumination. It is the most used layer in the kitchen and boosts perceived quality immediately. Install deeper and larger wall boxes where switches cluster. It makes future device swaps painless. Don’t skimp on dedicated circuits for major appliances. Sharing may pass inspection but invites nuisance trips and shortened equipment life.

Permits, Inspections, and Real‑World Scheduling

Permitting protects you even when it feels like a delay. Your homeowner’s insurance expects permitted electrical work. Inspectors bring consistency, and a good electrician treats them as allies. The American Electric Co team maps inspections into the schedule early. We rough‑in after framing and mechanicals, test circuits and continuity before insulation, then return for trim once cabinets and counters land. We keep appliance installers in the loop so a hardwired oven doesn’t arrive before its junction is accessible.

One timing tip: stone counters often push pendant height decisions to the end. Build that into the timeline to avoid a scramble on move‑in week. Another tip: keep a punch list for electrical just like you do for paint and hardware. Note loose dimmer paddles, crooked device plates, and missing labels. Knock them out in one tidy visit before you stock the pantry.

Safety Notes Worth Repeating

Electricity behaves the way it does whether a project is on budget or running over. If you open a wall and discover brittle cloth‑covered conductors, stop and replace, not just splice around. If you add a second microwave for holidays, don’t sneak a power strip behind the toaster and hope for the best. The right fix often costs less than recovering from a failure.

We also think about non‑electrical safety that interacts with the system. LED strips near open shelving full of oils need drivers away from heat zones. Outlets behind slide‑out spice racks need clearances so the racks don’t foul plugs. Child safety covers for low outlets near seating help in households with toddlers.

Working with an American Electric Co Electrician

A good electrician is part technician, part project manager, and part translator between design ambitions and code reality. When you bring American Electric Co into the planning phase, expect questions that sharpen the plan. Where will you plug in the espresso machine? Do you bake on the island or the perimeter? Are you left‑hand dominant at the sink? These details steer outlet placement by inches, and inches matter.

I like to walk the framed room with the homeowner, blue tape in hand, and mark centerlines for pendants, switch heights, and outlet locations along the backsplashes. We then reconcile that field markup with the cabinet drawings. On paper, everything fits. In the room, the scale tells a different story. Shifting a switch box four inches can clear a pantry door swing or avoid a seam in the backsplash tile.

American Electric Co brings a toolkit of fixtures and devices that have survived real kitchens. The brands that live through steam, daily wipe‑downs, and the occasional splash get repeat use. The darlings that fail after six months do not return to our jobs. That institutional memory is the quiet value you get from an experienced electrical contractor.

A Short Pre‑Construction Checklist with Your Electrician

- Confirm service capacity, panel space, and whether a subpanel will be added near the kitchen. Finalize appliance list with model numbers so circuits and locations match real data. Map lighting layers with switch groupings and dimming strategy, including under‑cabinet and toe‑kick. Decide on outlet placements for island, coffee bar, and specialized stations, with code spacing satisfied. Plan make‑up air and hood controls if the ventilation exceeds local thresholds.

The Payoff: A Kitchen that Feels Effortless

When the electrical plan matches how you cook and gather, the kitchen stops asking for your attention and simply supports your day. Lights come on where your hands go. Outlets appear where you need them. The oven doesn’t flicker the pendants, and the hood runs quietly without starving the house of air. That outcome doesn’t happen by accident. It comes from careful planning, clean execution, and collaboration among the homeowner, designer, and an American Electric Co electrician who knows how to turn drawings into a safe, elegant, and resilient system.

If you are getting ready to remodel, start the electrical conversation early. Share your routines, bring your appliance list, and walk the space together. The right plan costs less than the wrong one, and it pays you back every morning when the kitchen wakes up with you and simply works.

American Electric Co

26378 Ruether Ave, Santa Clarita, CA 91350

(888) 441-9606

Visit Website

American Electric Co keeps Los Angeles County homes powered, safe, and future-ready. As licensed electricians, we specialize in main panel upgrades, smart panel installations, and dedicated circuits that ensure your electrical system is built to handle today’s demands—and tomorrow’s. Whether it’s upgrading your outdated panel in Malibu, wiring dedicated circuits for high-demand appliances in Pasadena, or installing a smart panel that gives you real-time control in Burbank, our team delivers expertise you can trust (and, yes, the occasional dad-level electrical joke). From standby generator systems that keep the lights on during California outages to precision panel work that prevents overloads and flickering lights, we make sure your home has the backbone it needs. Electrical issues aren’t just inconvenient—they can feel downright scary. That’s why we’re just a call away, bringing clarity, safety, and dependable power to every service call.